PLATING ON SPECIAL MATERIAL

SPECIAL

Plating is used for a variety of purposes, from the shift to plastic for weight reduction in automobiles, to electromagnetic shielding in aerospace and medical equipment applications.

Plating on Magnesium Alloys

High Corrosion-resistance Plating on Magnesium Alloys

-

Magnesium is an abundant resource, and is the lightest metal material that can be used. It is more recyclable than plastic, and more environmentally friendly to produce than aluminum, leading to an increase in its use in Europe in such items as cars, cellular phones, and computers. However, due to its difficulty to machine, and its poor corrosion resistance (electrolytic corrosion), its uses have been more limited than aluminum. And though recent advances have made precision machining of magnesium alloys possible, the most common surface treatment after conversion coating is painting, and it has been considered to be a difficult material for plating to give a true metallic appearance.Here at Tsukada Riken, we have used our many years of decorative plating experience to develop the technology to plate magnesium alloys with a coating that is both visually decorative and functionally corrosion resistant. We can increase the usability of magnesium alloys through our plating process, which provides corrosion-resistant reliability and mass production with minimal rejects.

-

-

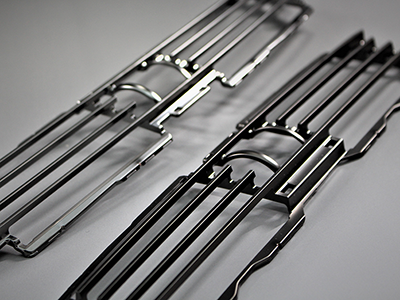

Cellular Phone Parts

-

Automotive Parts

-

| External Uses | It can impart a metallic look not possible with paint. And functional plating provides a coating that is suited to applications requiring friction reduction. |

|---|---|

| Added Conductivity | Highly conductive plating is ideal for applications like cellular phones and computers, which require noise reduction. The appearance and conductivity from the plating process are superior to that of anodization. |

| Wear Resistance | Much more resistant to wear than paint. |

| Shock Resistance | Far more resistant to shock than paint. |

Plating on Carbon Nanotubes

mproved Characteristics from Electroless Plating on VGCF ~ What is VGCF? ~

VGCF (Vapor-Grown Carbon Fiber) is one kind of mass-produced carbon nanotube.They are used in the production of lithium batteries, and by adding them to the positive and negative electrodes, input/output and durability characteristics are increased.

We’ve succeeded in electroless nickel coating of nanocarbon!!

-

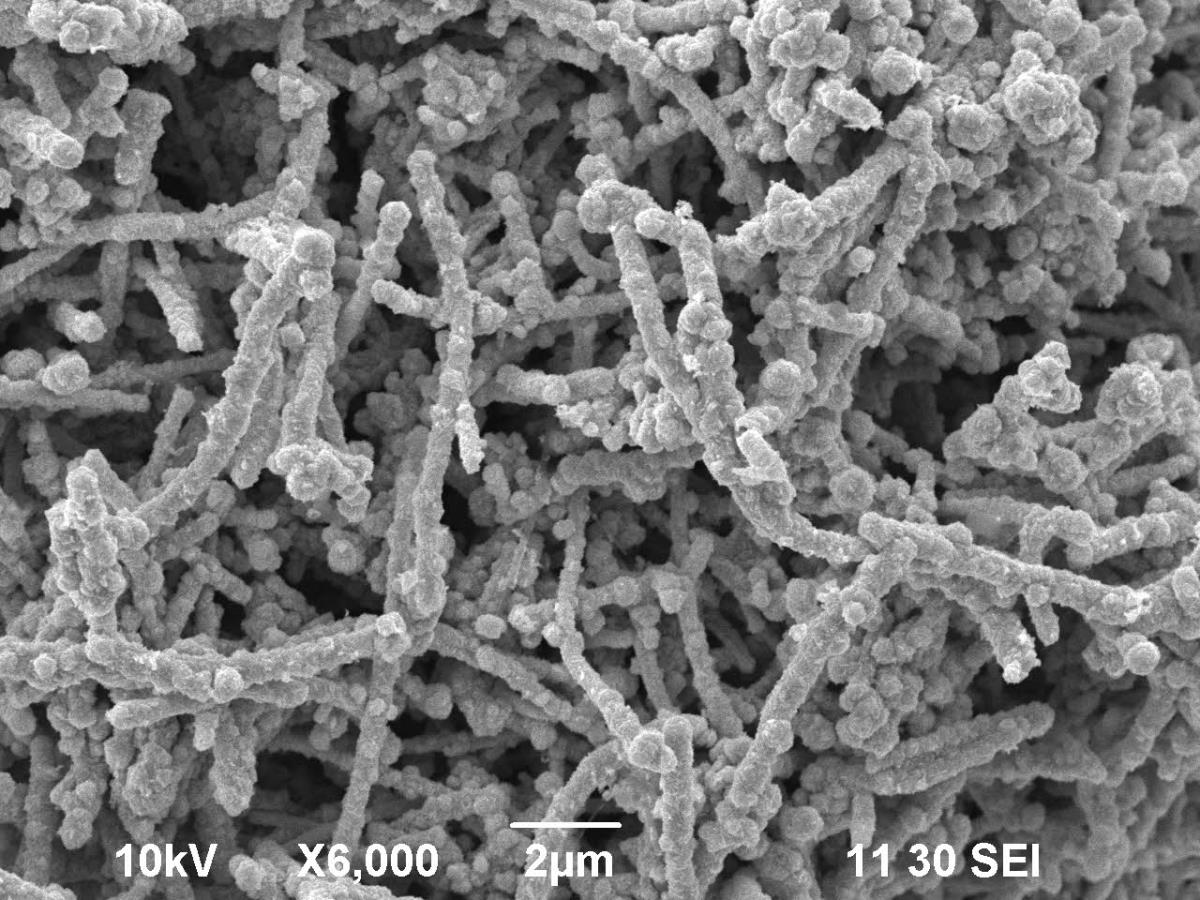

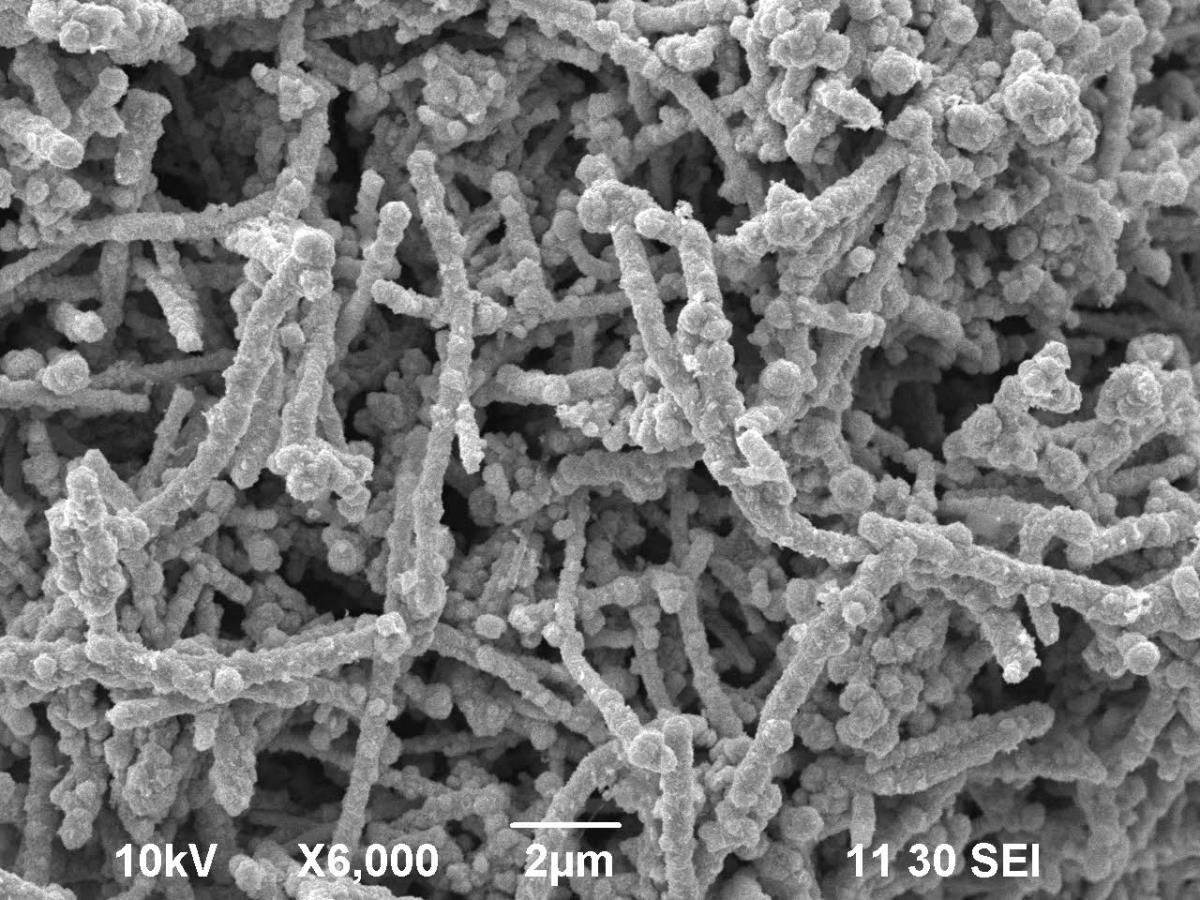

Nickel Coating Nanocarbon(Electron Microscope Photo)

-

High Expectations for More New Developments!!

Working in conjunction with Shinshu University Department of Engineering professors Morinobu Endo and Shinsuke Arai, we succeeded in developing a “Production Technology for Electroless Nickel Coating of Nanocarbon”. With this technology, we can use electroless plating to deposit nickel particles onto the surface of VGCF (Vapor-Grown Carbon Fiber), resulting in a VGCF/Ni composite. If this is applied to resin, it becomes a high-function nanocomposite that displays strength and electromagnetic shielding properties.

When Vapor-Grown Carbon Fiber (VGCF), one type of mass-produced carbon nanotube, is mixed into resin, it doesn’t disperse without interface bonding, so functionality and strength are not compromised. With this newly developed technology,

the material can be used in applications like cell phones and laptop computer housings, where enhanced strength, electromagnetic shielding, and thermal conductivity are desirable. We can expect even more new developments to make use of the functionality of plating.

-

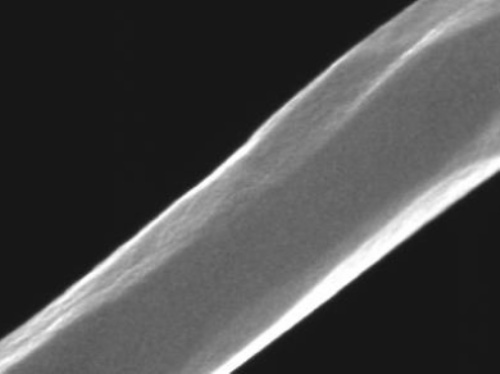

VGCF

-

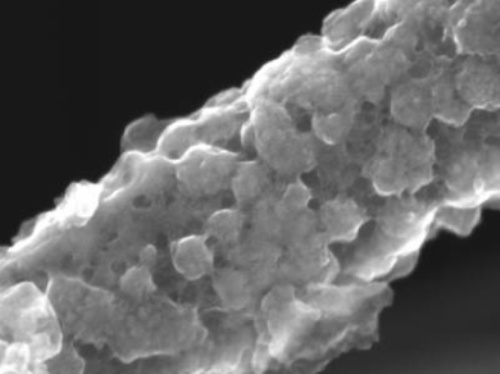

Nickel Coating VGCF

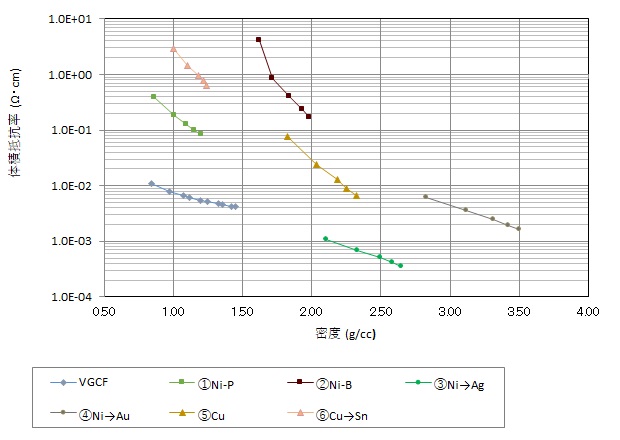

Results of Particulate Resistance Measurements

-

Using electroless plating process on VGCF provides lower resistance values with Au and Ag plating than simple VGCF.

-

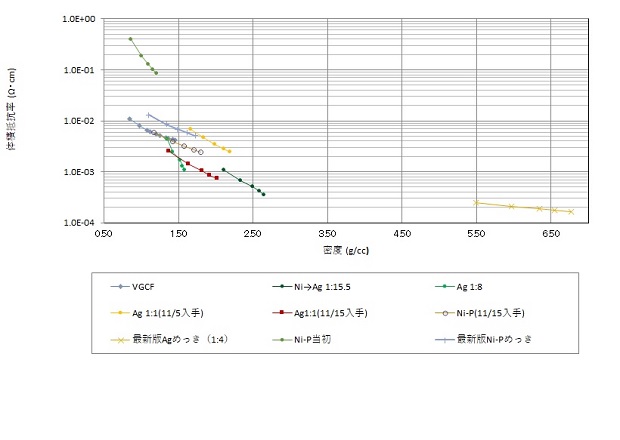

The resistance value decreases for the VGCF/Ag weight ratios and plating processes.

Anticipated Characteristics and Applications

The functionality (rigidity, heat conductivity, electric conductivity) inherent in VGCF is enhanced by covering it in nickel.The blending of metallicized VGCF into resin is better than unprocessed VGCF, and because the metal grips the resin,

deciduation of VGCF can be prevented. As a result, the functionality of the VGCF-resin composite is further enhanced. Currently, housings for laptop computers, etc., which require rigidity, use resin impregnated with CF,

but by switching the CF to VGCF, the properties of rigidity et al can be expected to improve.The use of nickel-coated VGCF can lead to the development of high-performance parts, and its increased conductivity can be used in fields requiring improved electromagnetic shield properties.

Examples of Uses for Nickel Coated Nanocarbon

-

Nanocarbon

-

Applications for Products requiring Rigidity and Electromagnetic Shielding

If it is used as a resin composite, rigidity, heat dissipation, and electromagnetic-shield (EMI shield) properties are improved.