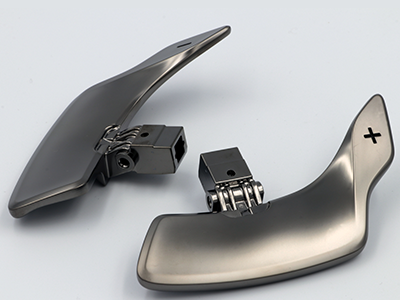

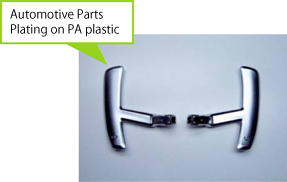

Plating is used for a variety of purposes, from the shift to plastic for weight reduction in automobiles, to electromagnetic shielding in aerospace and medical equipment applications. There is a wide range of functional plating,

including strongly adhesive plating for engineering plastics and high-performance super engineering plastics, plated wiring on three-dimensional molded objects (MID), plating for electromagnetic shielding, plating for increased hardness or friction reduction, plating to magnesium (the lightest metal), etc.

Plating on Engineering Plastics

ENGINEER PLASTIC PLATING

Uses of Engineering Plastics

-

-

Plastics are used in items all around us, but there are a great many different kinds of plastic. They are useful in lowering both weight and cost for such things as automobiles, cellular phones, and electronics. And by plating high performance resins known as engineering plastics and super engineering plastics, they can attain hardness, thermal conductivity, electric conductivity, shielding properties, etc. on par with metals, so we can expect to see them used in even more parts in the future.

What Are Engineering Plastics

Plastics can be largely divided into two types – thermoplastic and thermosetting. And thermoplastics, which are resins that become fluid and moldable when heated, can be divided into standard plastics and engineering plastics.

Engineering plastics are generally differentiated from standard plastics if they are heat resistant above 100℃, have a strength above 50 MPa, and have a Flexural Modulus of Elasticity above 2.4 GPa.

If the heat resistance is even higher, and able to withstand over 150℃ for long periods of time, the plastic is considered to be a super engineering plastic or special plastic.

Plating on Engineering Plastics

Engineering and super engineering plastics are considered to be difficult materials for plating, and in most cases standard plastic plating processes (for use with ABS) are not sufficient. We created a special department 20 years ago, tasked with finding ways to plate these materials, and have succeeded in creating several processes that make such plating possible. And many resin manufacturers have brought us their new plastics, so we could develop new processes for plating on them.

Engineering Plastics Suitable for Plating

Adding plating to engineering and super engineering plastics helps give them the properties to replace metal parts. And we are also developing processes for MID (Molded Interconnect Devices), which are being developed in western countries.。

| Standard plastics | ABS, Heat-resistant ABS, Flame-retardant ABS, PC/ABS |

|---|---|

| Engineering plastics | PC, PBT, PA, SPS, POM, PPE |

| Super engineering plastics | PES、PPS、PEI、LCP、PI、PEEK |

| Special plastics | PC/ASA, PU, Laser beam lithography materials, 2-color molded materials |

Development Projects

-

-

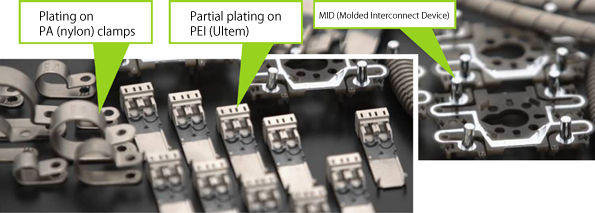

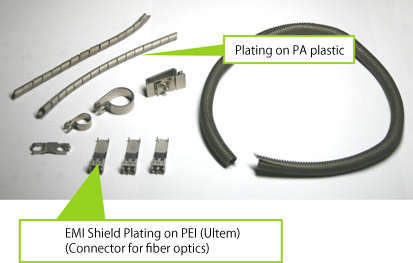

Developed technology for plating on PA (nylon)

Developed technology for plating on PEI (Ultem)

Developed technology for plating on PEEK

Developed technology for plating on LCP

-

-

We also perform plating on resins with glass filler, ceramics, glass, fiber, etc.

Even among the plastics listed above, there are some grades that are difficult to plate. We can recommend the best grade for plating.

We even accept one-off trial pieces. Please ask us.

EMI Shield Plating (Electromagnetic shield plating for plastic)

EMI SHIELD PLATING

In weight-saving applications for new-energy cars like EV and PHV…

the use of Electromagnetic Shield Plating on plastics is increasing!

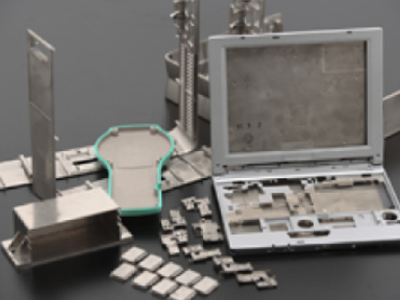

At Tsukada Riken, we are creating Electromagnetic Shield Plating on plastics to prevent electromagnetic interference for use in cellular phones, laptop computers, projectors, and other electronic devices.We can recommend the shielding for your needs, whether it be to prevent the emission of electromagnetic noise, or to protect against electromagnetic noise.

What is electromagnetic shielding?

When high-frequency current flows into a metal object, it causes electromagnetic noise, and this noise can disable electronic equipment.

Electromagnetic shielding protects against this damage.

Things that Emit Electromagnetic Noise: electronic equipment, motors, wires, etc.

Electromagnetic waves around us

Main Uses for Wavelength Bands

As the above demonstrates, electromagnetic waves are used for broadcast and radio transmissions.

These devices also emit electromagnetic noise, and affect each other.

In recent years, with the aims of automation, weight reduction, and cost cutting, the use of plastic parts has increased. However, unlike metal, plastic cannot block electromagnetic waves. With the realization of self-driving cars, the need for measures against electromagnetic interference has been increasing, and the use of shield plating on plastics for computers, office devices, and medical equipment has been garnering attention since 1985.

Effects of Electromagnetic Shield Plating

-

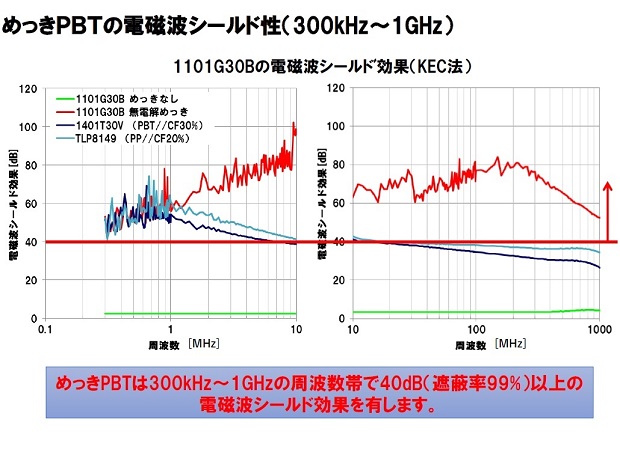

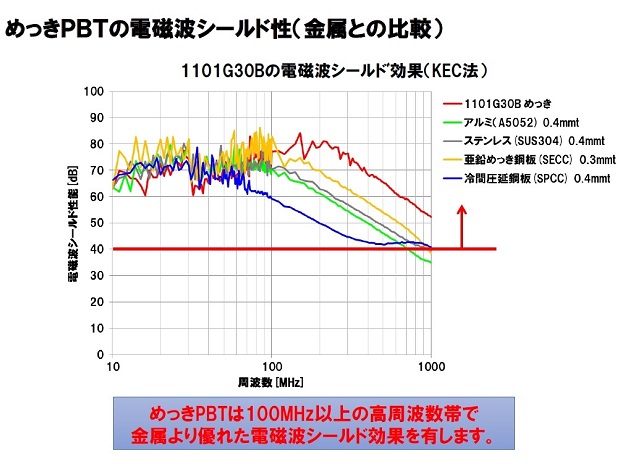

Shield Effect Comparison of Plastic with Shield Plating and CFRP (carbon fiber reinforced plastic)

Plastic with shield plating demonstrated much higher shielding effects than CFRP (carbon fiber reinforced plastic). -

Shield Effect Comparison of Plastic with Shield Plating and Metal Shield

Plastic treated with shield plating demonstrated better shielding effects than aluminum, stainless steel, copper plate, or steel plate.

As can be seen from the above, by applying electromagnetic shield plating to plastic,

high shield values for 10MHz~1GHz can be attained.

Some plastics that can be used for electroless shield plating.

-

- Polypropylene (the first shield plating grade created)

- Strengthening of PET glass

- PPS (150℃ → -40℃ no change in resistance in 2000 cycles)

- ABS, ABS/PC (These are often used for decorative plating)

- Polyester fiber, aramid fiber (often used as gaskets)

-

- Polyetherimide, liquid crystal polymer (proven super engineering plastics)

- PBT (Polybutylene terephthalate) (used in connectors)

※Adhesion varies with different grades, so evaluation is necessary.

※Other plastics can also be used for electromagnetic shield plating. Please ask us.

Properties of Electromagnetic Shield Plating

・Compared to electromagnetic shields using metals, plastic helps to lower weight, improve mileage, and lower costs.

・It can be seen that in the 10MHz~1GHz range, the shielding effects equal or surpass those of metal.

In recent years, electromagnetic shield plated plastic is seen as one way to reduce weight and increase fuel efficiency in the next generation of automobiles.Other tests and evaluations have been performed. We will also test for other than the above-listed materials, so please contact us for more information.

Sample Uses

-

-

- Fire engine control panels

- Various kinds of connectors

- Medical equipment

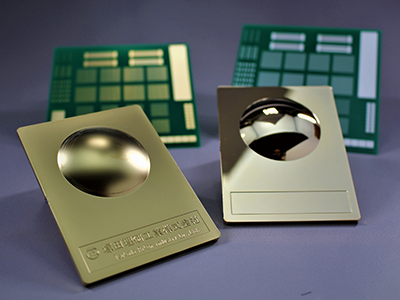

Plating with Precious Metals

PRECIOUS METAL PLATING

-

- Precious metals like gold, silver, and platinum are often used for decorative purposes, but they are also important plating mediums for use as functional plating. We can perform plating with gold, silver, platinum, and palladium. These precious metal plating surfaces have many useful qualities, such as conductivity, corrosion resistance, anti-bacterial, and so on. We accept orders for prototypes. Please contact us.

| Precious Metal | Cost | Characteristics |

|---|---|---|

| Gold | 5 | ・Very strong resistance to corrosion by heat, humidity, oxidation, or other chemical reactions (normal acidity and alkaline). ・Minimal change to contact resistance value due to passage of time. ・Superior conductivity of electricity and heat, and good soldering properties. |

| Silver | 2 | ・Silver ions have strong bactericidal properties and are widely used in antimicrobial products. ・Even better electric conductivity than copper. ・Superior ductility and malleability. ・Using its strong antibacterial properties, use for antimicrobial products has increased, and it is also attracting attention for its deodorizing properties. ※Silver discolors quickly on contact with sulfur or arsenic compounds. This quality lead silver to be used historically in upper-class society as silverware, to detect the presence of poison in food. |

| Platinum | 4 | ・Its surface, like white gold, has a soft, bright shine to it. ・Resistant to liquids like sweat, and often used in every-day accessories. |

| Palladium | 3 | ・Of the white metals, it is less expensive than platinum or rhodium ・Due to its low cost, it is used as an undercoat for gold plate, to enhance corrosion resistance and shininess. ・It does not discolor |

Plating for Rigidity/Lubrication/Abrasion Resistance

STIFFNESS, SLIDABILITY, FRICTION RESISTANCE PLATING

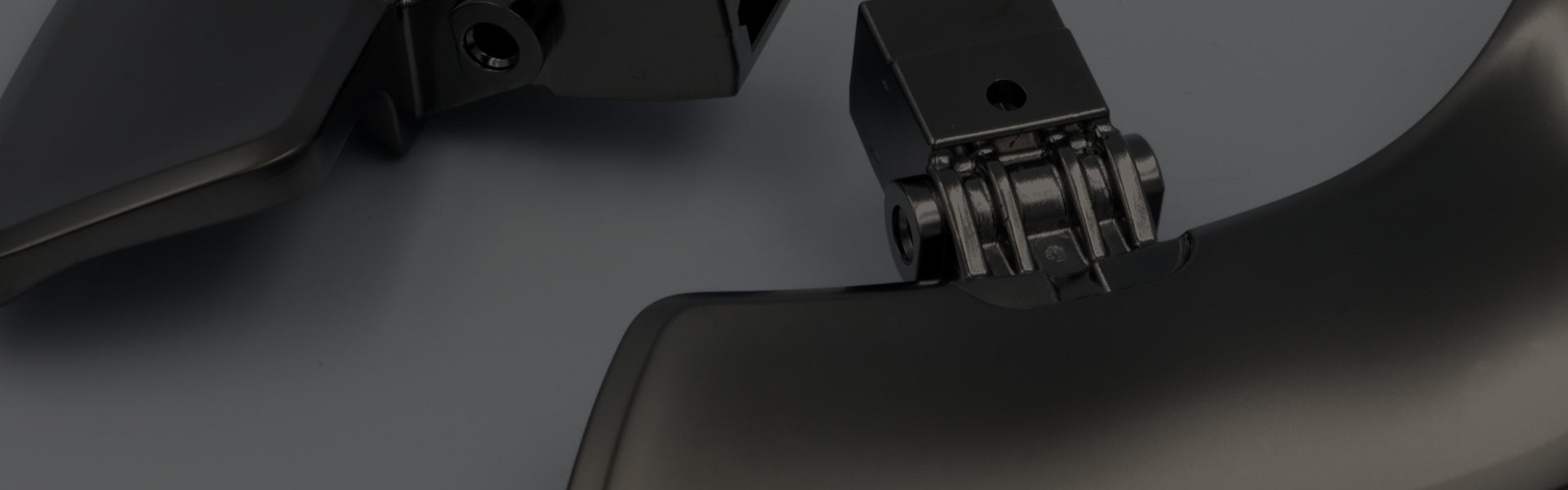

Rigidity

If thin-walled molded objects or objects with fine parts are plated with a coat of a rigid metal, it is possible to greatly increase the rigidity of the object. They can be given not only the strength of a machined object, but also properties such as heat dissipation and electromagnetic shielding. Replacing aluminum or magnesium parts with these plated plastic parts can help with factors including cost reduction and weight reduction.

-

Before plating

-

After plating

By electroplating a uniform 10µm coat of copper,

the flexural modulus (of ABS resin) is

Without plating: 2500[Nm]

↓

With plating:10000[Nm]

This has seen use in camera housings.

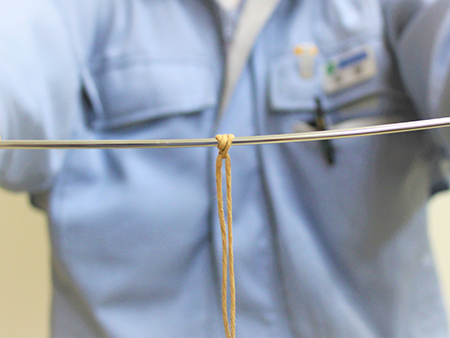

Lubrication and Abrasion Resistance

Lubrication and abrasion resistance are necessary for parts in mechanical devices that are in contact with other parts.

With our electroless plating technology, we can apply plating to the surfaces of various types of plastic, including engineering and super engineering plastics, that imparts them with lubrication and abrasion resistance properties. By combining them with plastics with high heat resistance or hardness, the range of potential applications is further increased.

Plastic products coated with a lubricating plating are low-wear and slide smoothly, improving their abrasion resistance. And with plating, the coat can also be imbued with conductivity.

For more information, please ask us.