Quality Control / ISO9001

ISO9001

-

-

Employing our skilled techniques, along with leading-edge monitoring equipment, analytical instruments, and reliability testing devices, we aim for zero-reject production by performing thorough management of the production processes.

We check solutions daily for the production process, test products for reliability after processing, take immediate measures to resolve problems that arise, and monitor surface results at micron levels. We make full use of the latest technologies to provide the quality that our customers expect, and using the ISO9001 Quality Management System, our methods are evolving daily.

Our greatest theme as a company is to accurately assess the quality needs of the present, and combine our refined techniques and the latest equipment to be a company that is always trusted.

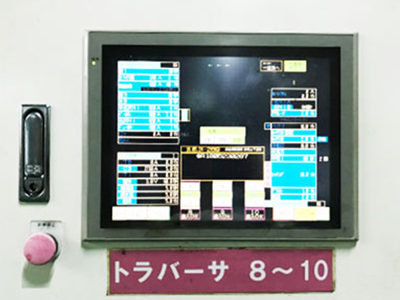

Production Management System

Production Management System

-

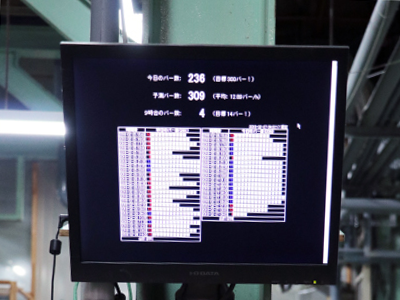

We have implemented our own production management system, by which we manage the product flow from receiving to shipping by computer. We can achieve more efficient production by being constantly aware of what process each item is undergoing. Also, the complex plating conditions for each and every piece are entered into a database. And by using bar-coded process charts at the processing sites, the work is simplified, and defects due to human error have been decreased.

The system is structured so that the data for the times and conditions of each plating process is automatically accumulated, simplifying the tracking of the history of plating conditions for each item. -

-

Production Management System

-

Production Management System

-

We are evolving our production system with the goal of achieving even shorter delivery times with unwavering quality.

Measuring / Analysis Devices

Product Measurement / Analysis Devices

-

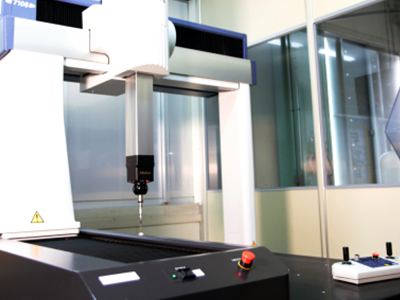

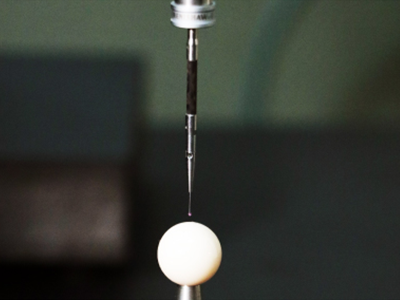

This is a precision measuring device that can automatically check for contraction or deformation of the plastic in 3 dimensions after plating. It has superior automatic processing capacity, and can measure contour deviations and profile contours of pieces with curves surfaces.

-

-

CMM (Coordinate Measuring Machine)

-

CMM (Coordinate Measuring Machine)

-

-

Microscope

This microscope can magnify the surface up to 300 times for observation. It displays color images useful for analyzing flaws or for observing the coat of plating for newly developed processes.

-

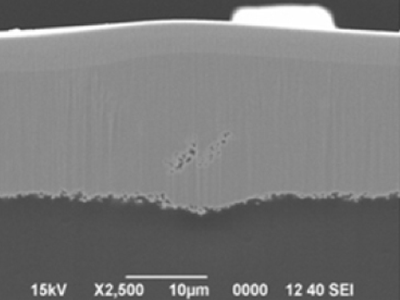

Cross-section Polisher(CP)

This is used to polish soft materials that are usually difficult to give a perfect mirror finish, or to make cross-sections on hard-to-cut materials like glass and ceramic.

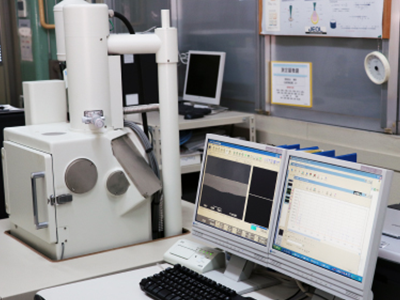

high-performance electron microscope

-

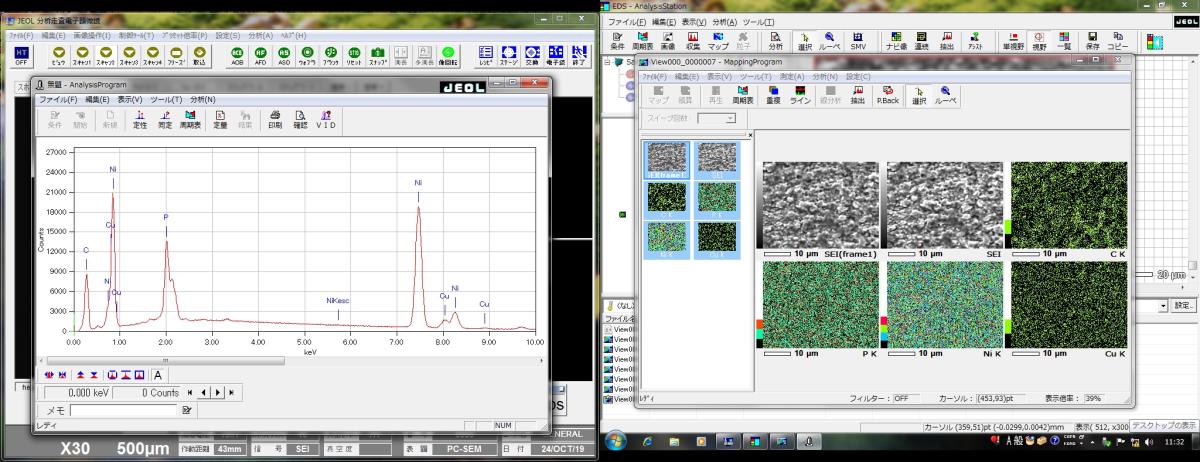

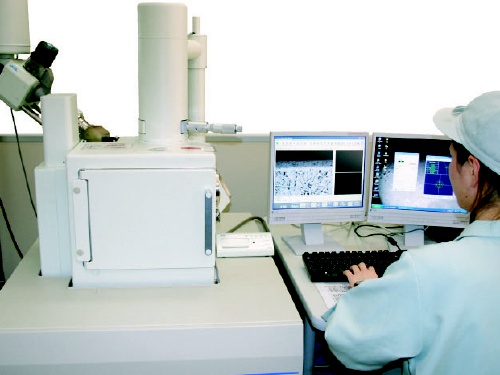

This high-performance electron microscope can magnify the surface up to 300,000 times, and also has surface composition analysis function. It can observe structures that would be crushed using standard machine polishing. And since it can analyze the surface composition being observed, it is useful in determining the causes of flaws.

-

-

Scanning Electron Microscope with Surface Composition Analysis function

-

Result of Cross-section Observation

-

-

Elemental Analysis Monitor

-

In order to quickly determine the causes of flaws, and prevent their repetition, we make full use of Microscopes and Scanning Electron Microscopes (SEM) to analyze the materials, as well as the surface and cross-section of the plating.

And when problems arise after plating a material or mold, we use the latest analytical equipment to provide clear explanations to our customers, and offer our advise as to the best countermeasures.

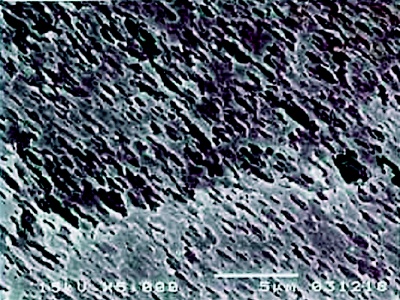

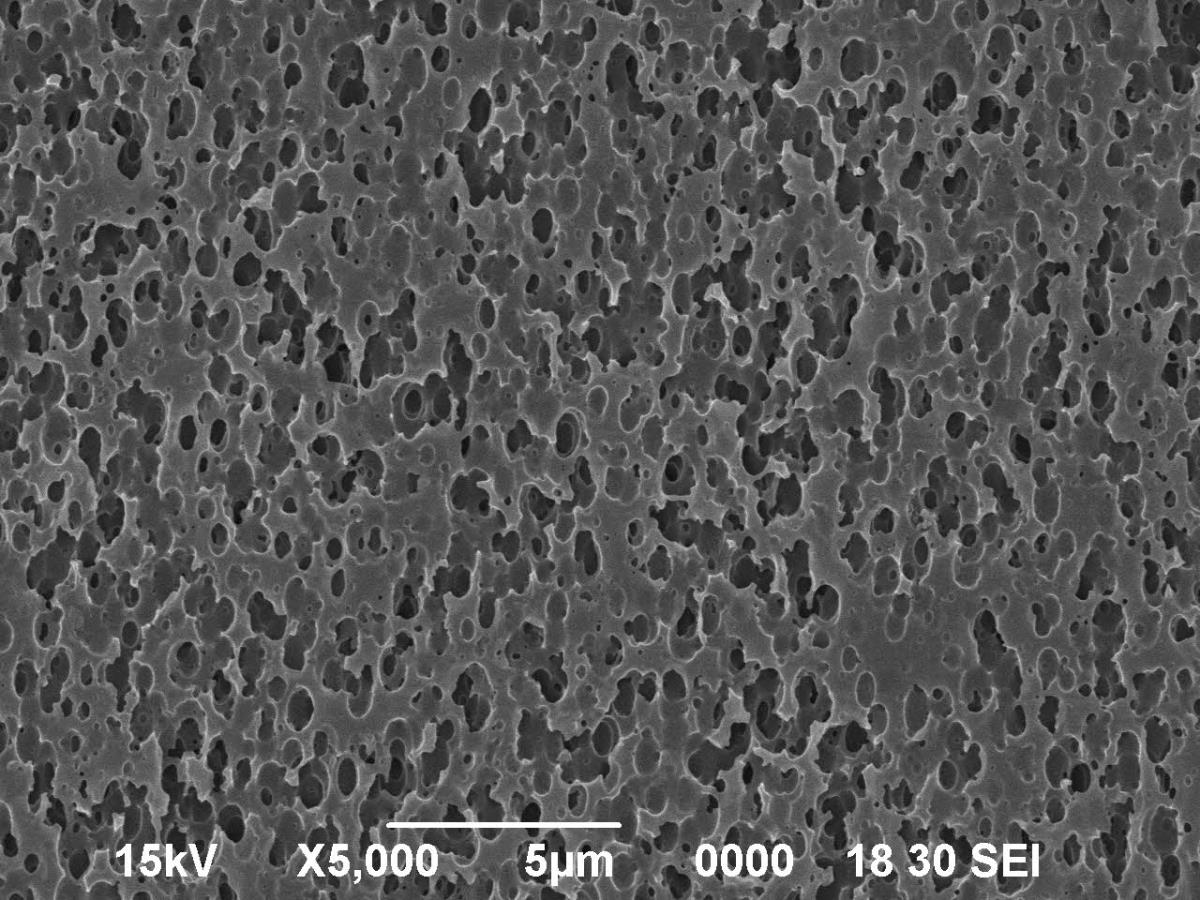

Material Surface Observation using the SEM

-

We use the 300,000x magnification to best determine the causes and solutions for any flaws.

-

-

Result of Surface Observation after Etching

(Section with Defective Condition)

Poor adhesion decreases reliability -

Result of Surface Observation after Etching

(Section with Good Condition)

Condition of Etching with normal adhesion

-

Liquid Analyzer

We constantly make use of high-precision equipment to attain unwavering environmentally friendly quality.

-

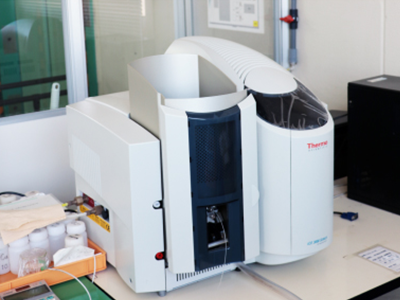

ICP Optical Emission Spectrometer

This allows for highly precise qualitative and quantitative analysis of metallic elements in the plating solution, which aids in the stable management of the solution.

-

Capillary electrophoresis apparatus

This allows for quantitative analysis of the plating solution. It can measure the ion concentration, and is used for measuring the chloride and sulfate ions in the plating solution.

Quality Control System

Combining our refined techniques and the latest equipment, we strive to be a company that is always trusted.

Employing our skilled techniques, along with leading-edge monitoring equipment, analytical instruments, and reliability testing devices, we aim for zero-reject production by performing thorough management of the production processes.

We check solutions daily for the production process, test products for reliability after processing, take immediate measures to resolve problems that arise, and monitor surface results at micron levels. We make full use of the latest technologies, evolving our methods daily, to provide the quality that our customers expect.

Our greatest theme as a company is to accurately assess the quality needs of the present, and combine our refined techniques and the latest equipment to be a company that is always trusted.