Plating on Print Circuit Boards

PRINTED WIRING BOARD PLATING

-

- As a top plating manufacturer, we at Tsukada Riken use the latest equipment and leading-edge technology to actively develop surface processing technologies for print circuit boards in order to accommodate our customers’ requirements for more miniaturization, ultra-high density, and precision. In an environment of strict quality control and cost limitations, we cooperate with the circuit board manufacturers to lower costs for our mutual benefit and prosperity.

Examples of use

- We have introduced a line that uses bar-code management with complete automatic control, which provides stable quality for the range from mass production to random, small-lot multi-object production.

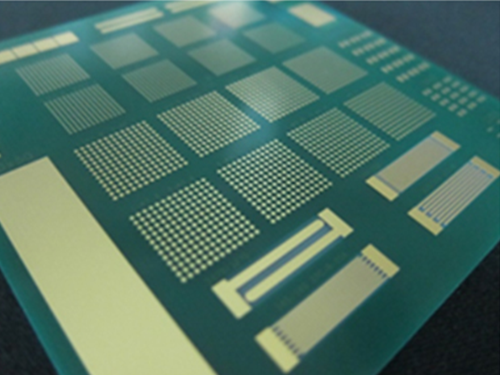

- We can mass-produce electroless gold plating on print circuit boards with line/space margins of 20-20μm, which is considered to be the minimum limit.

- We have established methods for Ni-Pd-Au plating, which is excellent for wire bonding and bonding to lead-free solder.

- We can accommodate tin plating, which is environmentally friendly and has superb solder wettability and bonding properties.

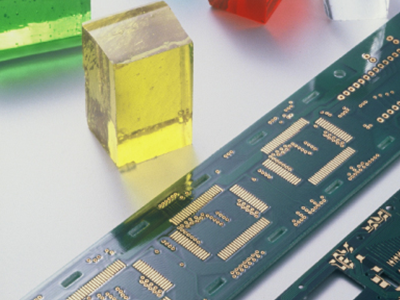

- We can perform nickel gold plating on package substrates, module substrates, flexible substrates, HDI multi-layer boards, and ceramic substrates.

- We can deal with electroless nickel plating black pad corrosion using immersion-reduction gold plating and Ni-Pd-Au plating.

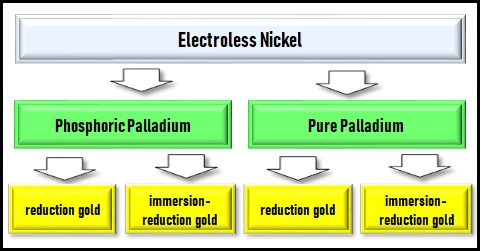

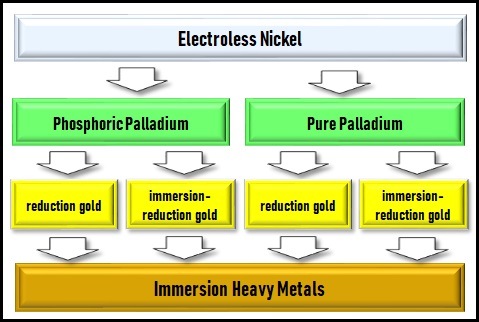

- We can perform 2 types of electroless palladium plating: phosphorous palladium and pure palladium.

- We can control the thickness inconsistencies of electric nickel-gold plating.

Plating Process ~ Gold Plating on Print Circuit Boards ~

STEP. 1

Surface Processing of Circuit Boards

-

■Polishing (Buffing/Brush Polishing)

■Chemical Polishing

■Jet scrub polishing

■Plasma Surface-modification

-

-

Jet scrub polisher

-

Plasma Surface-modification Device

-

STEP. 2

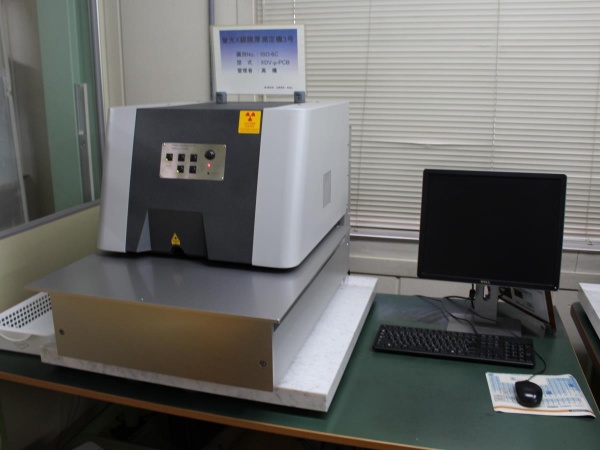

Preliminary Plating Test

-

■Preliminary Plating Board Machining

■Preliminary Plating Inspection (visual, thickness)

■Notice of Mass Production Start Permission

-

-

Fluorescent X-ray Coating Thickness Gauge

-

Test Piece

-

STEP. 3

Electroless Ni-Au Ni-Pd-Au Plating

-

■Degrease – Soft etch – Pre-dip - Activator

■Electroless Nickel Plating

■Electroless Palladium Plating

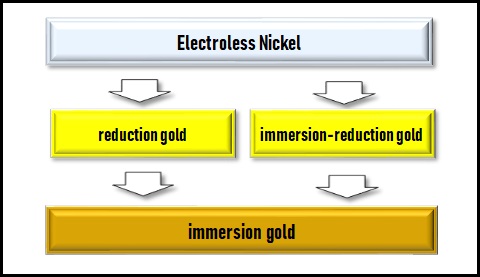

■Electroless Thin Gold Plating(immersion gold, immersion-reduction gold)

■Electroless Thick Gold Plating (reduction gold)

-

-

Electroless Plating Line

-

Electric Plating Line

-

STEP. 4

Final Surface Washing – Quality Assurance

-

■AQUAPASS (Ultrasonic Cleaner/Drier)

■Inspection (Quality Assurance) - Shipping

■Durability Test Evaluation (SEM monitoring wire bonding tensile strength) -

-

Test Piece

-

AQUAPASS

-

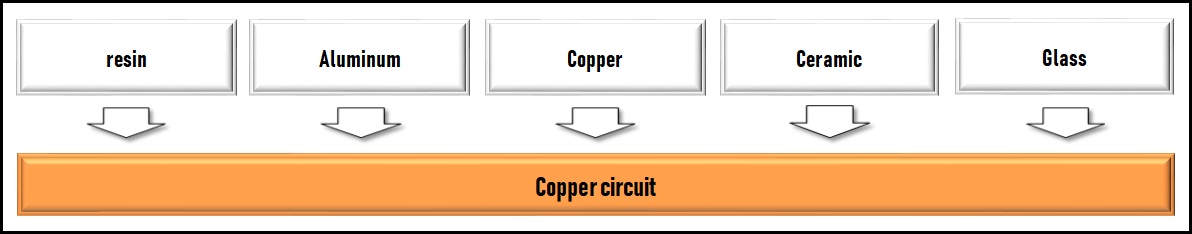

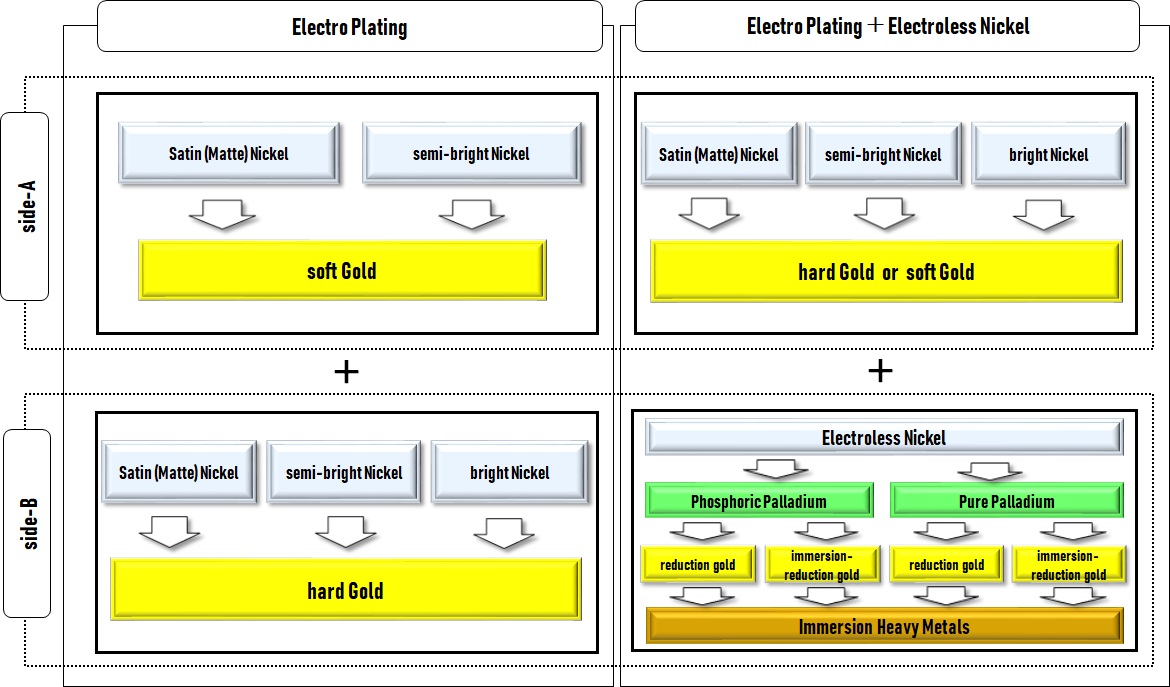

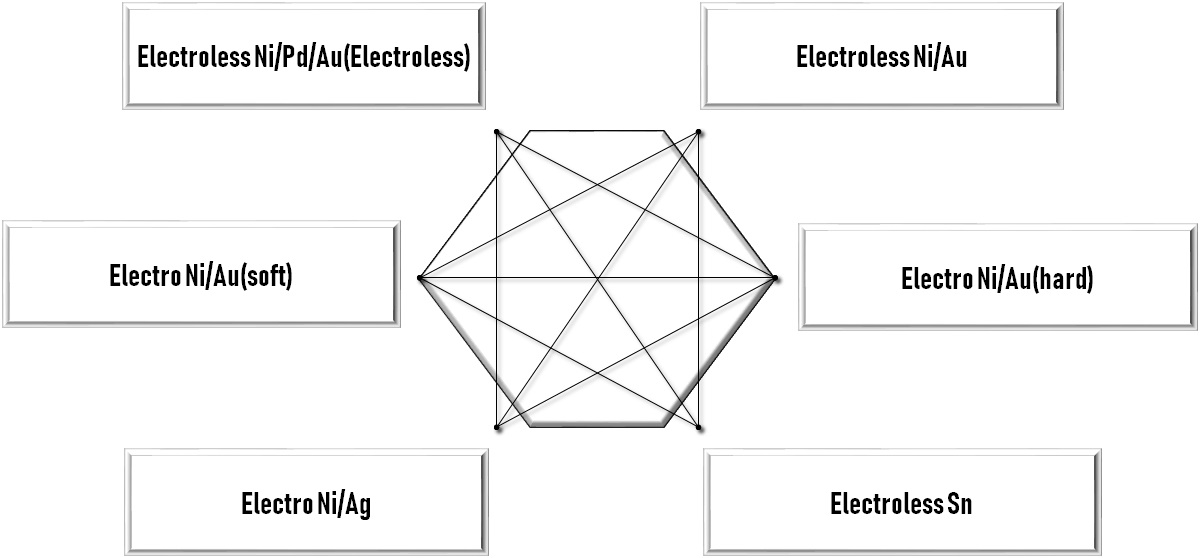

List of Plating on Print Circuit Boards

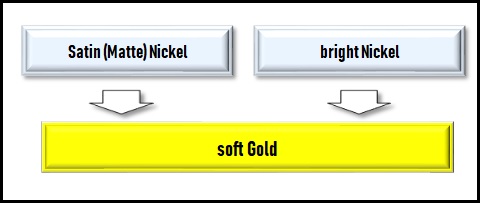

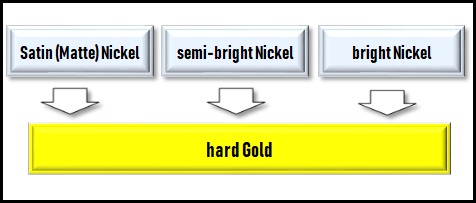

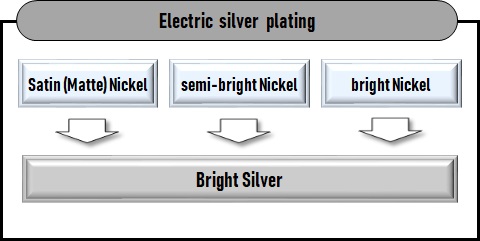

Electric nickel gold plating

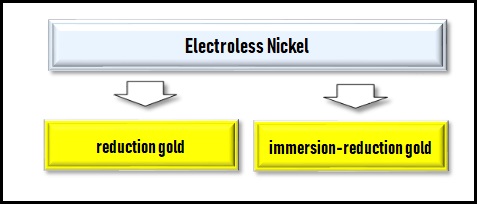

Electroless nickel gold plating

Electroless nickel palladium gold plating

Plating other than gold plating

Plateable substrate type

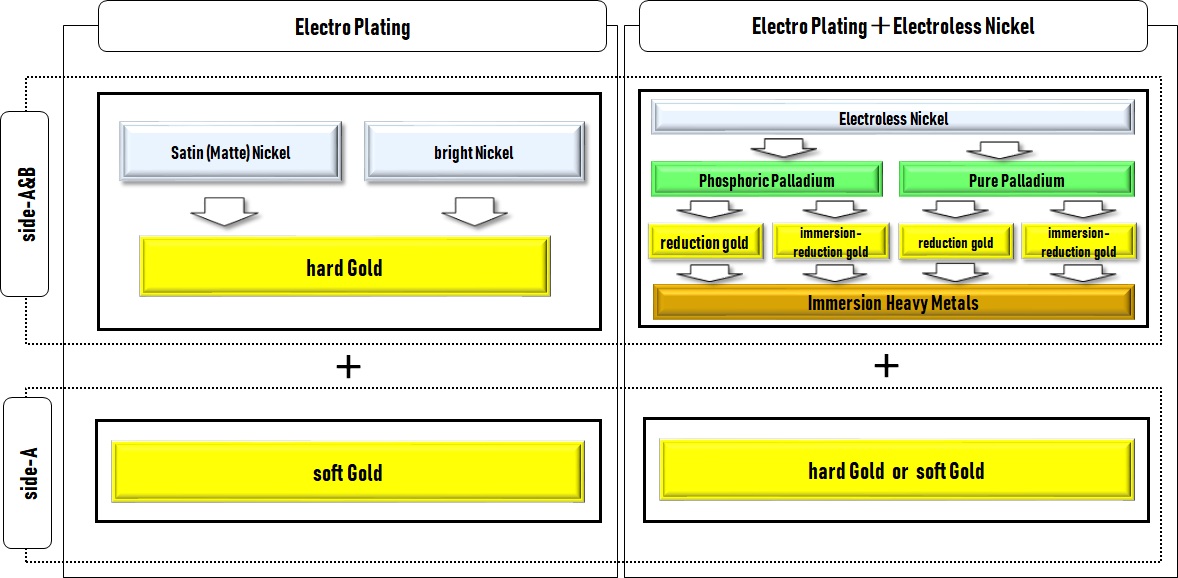

Composite plating

2 Color plating

There are 15 combinations to choose from

Double plating

We want to do partial plating!

-

-

-

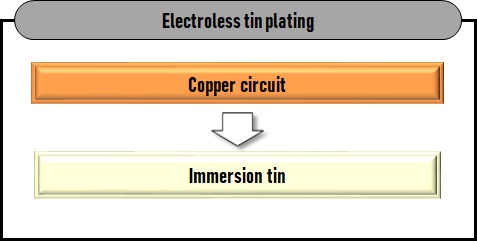

<Electroless Plating >

・We can perform this using tape masking process.

< Electric Plating>

・We can manufacture objects formed with dry film masks.

Chart of Print Circuit Board Plating

Plating specification basic information

| Plating Specifications | Possible Plating Thicknesses | Board Thickness | Maximum Object Size | Minimum Object Size | |

|---|---|---|---|---|---|

| Electric | Nickel Plating | 0.50 - 20.0μm | 0.06 - 4.5 mm | 410 × 1,150 mm | Smaller than 100×100mm requires consultation about the frame setting. |

| Gold Plating (hard) | 0.03 - 2.0μm | ||||

| Gold Plating (soft) | 0.03 - 2.0μm | ||||

| Silver Plating | 0.03 - 10.0μm | 610 × 1,120 mm | |||

| Electroless | Nickel Plating | 0.50 - 20.0μm | 0.06 - 8.0 mm | 700 × 1,220 mm | |

| Phosphorous Palladium Plating | 0.03 - 0.15μm | 700 × 860 mm | |||

| Pure Palladium Plating | 0.05 - 0.40μm | 700 × 1,220 mm | |||

| Thin Gold Plating (immersion-reduction gold) | 0.01 - 0.07μm | ||||

| Thin Gold Plating (immersion-reduction gold) | 0.01 - 0.07μm | ||||

| Thick Gold Plating (reduction gold) |

0.07 - 0.80μm | ||||

| Tin Plating | 0.10 - 1.60μm | 680 × 760 mm | |||