We perform a wide range of plating processes: car interior and exterior cladding and electronics, plumbing fixtures, and parts for high-speed railways and aviation applications. From luxurious satin colors to jet-black finishes, we have a basic list of 56 colors (please refer to our Samples Catalogue), yet we are also constantly keeping pace with the latest color trends. We are able to accommodate products as large as 2000mm x 900mm. In order to expand the possible variations of car interior sound-deadening and decoration, we can also perform partial plating. With our proprietary TP Mask Method, we can perform partial plating without leaving any residual masking solvent.

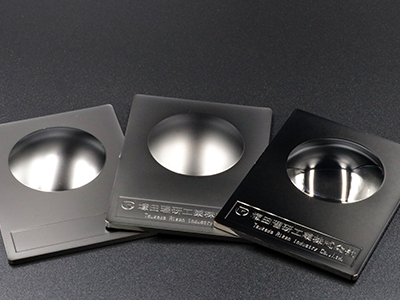

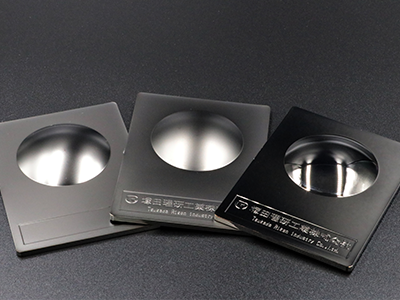

Partial Plating

PARTIAL PLATING

Partial Plating with our Proprietary TP Mask Method

Most partial plating uses masking solutions.

However, it is very difficult to remove the masking solution after plating, and often the parts are shipped with residual masking solution, or with the residual solution hidden under a layer of paint.

However, this cannot be used on parts where high degrees of precision are required, so an additional process is required after plating to remove the masking solution.

This step results in higher cost, slower delivery date, and lower quality. Furthermore, if the masking solution dissolves into the plating solution, it could result in defective plating.

Here at Tsukada Riken, we use our proprietary TP masking method, which allows us to remove the masking solution during preparation for the plating process, making it possible to perform plating while leaving sections of the base material uncovered. The final result is beautiful, and even though it accomplishes partial plating of the base material, it can be performed at low cost and in short time.

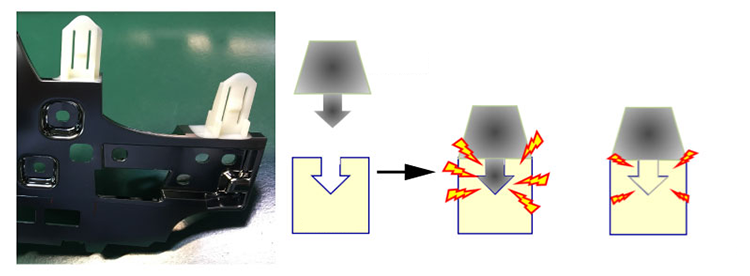

Preventing Squeaking

When plated parts come into contact with other plastic parts, the rubbing of the two pieces results in a squeaking sound. In order to prevent this, non-woven fabrics etc. were applied to the surfaces of the assembly areas, but TP masking and the double-mold method can be used to prevent such noises. Also, increased measurement precision prevents gaps between the parts. Many domestic high-end cars use these methods.

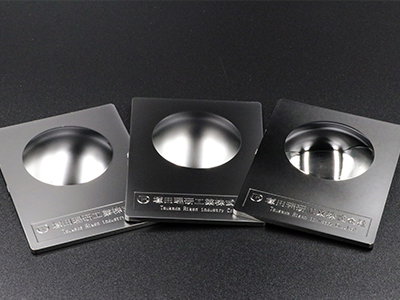

Comparison

-

Conventional Masking Method (right photo)

TP Masking Method (left photo) -

We can perform plating using conventional masking & plating without leaving masking solution

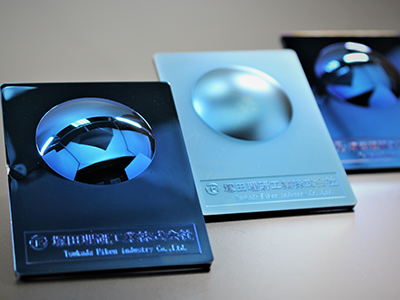

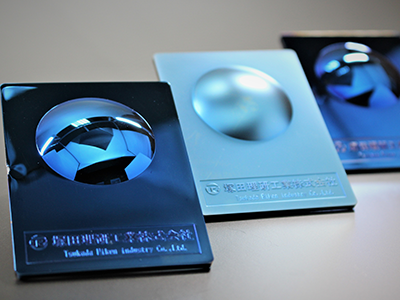

Black Plating

BLACK PLATING

Kinds of Black Plating

We have added Jet-black plating (B2, B3) and a bluish black chrome plating (TB) to our lineup of black plating colors. Until now, the black plating had been alloy plating (nickel-tin alloy, etc.), but they weren’t very resistant to corrosion or fingerprints, making them difficult to use in automotive applications. But the new jet-black plating and bluish black chrome plating have a higher level of corrosion resistance, and are already being used in car interiors.

-

Black Trivalent Chromium Plating<TI>

This is an environmentally friendly trivalent chrome plating. It has a deep, dark titanium-like color, and is especially popular for use in high-end car interiors. -

Jet-black Plating<B2、B3>

This is a darker black color than TI or TB. It is also called jet black tone. -

Black Trivalent Chromium Plating<TB>

This is an environmentally friendly trivalent chrome plating. It has a stronger blue color than TI.

| - | Blackness level | Characteristics | Corrosion Resistance | Proven Performance | Cost |

|---|---|---|---|---|---|

| TI |

|

Like C3 this black trivalent chrome plate was developed for hexavalent chrome-free etching. Darker black than C3, it has a titanium-like hue. This trivalent chrome is the most highly used in car interiors. | ◎ | ・Ext. auto parts ・Int. auto parts ・Fishing (reels) etc |

1.2 |

| TB |

|

This black trivalent chrome plate has more blue than TI. It is often used in high-end sports cars, etc. | ◎ | ・Int. auto parts | 1.4 |

| B2 |

|

Like B3, this jet-black plating has a deep, glossy black tone. It is slightly brighter than B3. | ◎ | ・Int. auto parts | 1.4 |

| B3 |

|

This is the blackest trivalent chrome plating with corrosion resistance for car interiors and exteriors. It has a brilliant black metallic look, also called jet-black. | ◎ | ・Int. and Ext. auto parts | 1.4 |

esides Black Plating, we also have a line-up of other colors, including gold and satin plating.For more information, please see our sample catalogue.

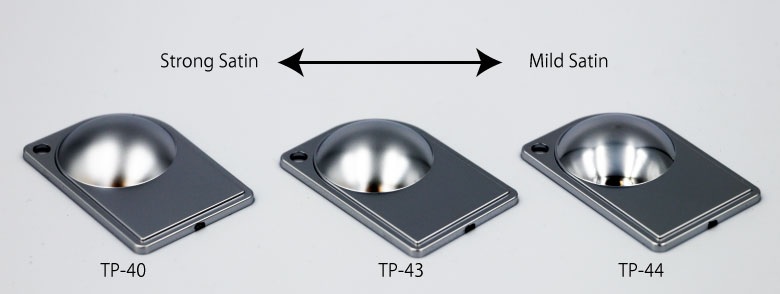

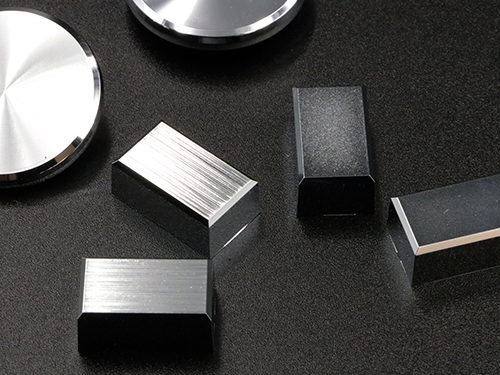

Satin Plating

SATIN PLATING

Satin Colors

During the plating process, even if the material doesn’t have a rough surface, the plating process can be used to give it a rough, satin finish.

Here, we can create three levels of satin finish, from strong satin finishes reminiscent of pearl or machined aluminum, to a luxurious milder satin finish with a softly glossy look.

TP-40:Beautiful pearly satin appearance

TP-43:Luxurious tone with a serene, softly glossy metallic feel

This satin finish is popular among European designers.

TP-44:Specially developed fine satin finish

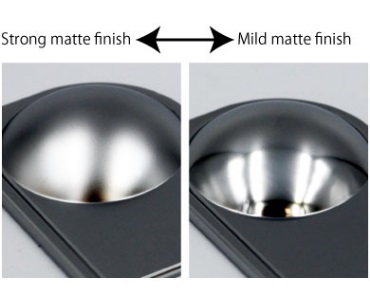

Shades of Satin Plating

-

-

Besides the “strength/weakness of the matte finish” in satin tones, there are also minor differences in the level of graininess.We realize that our customers all have their individual color requirements.

For example, in the case of car manufacturers, even the same manufacturer might want slight differences for different models.

By changing the plating conditions, we can adjust the strength of the satin effect, so we can also adjust the tones to match our customers’ needs.Also, by changing the outermost layer,

we can produce multiple colors, such as white, black, gold, etc.

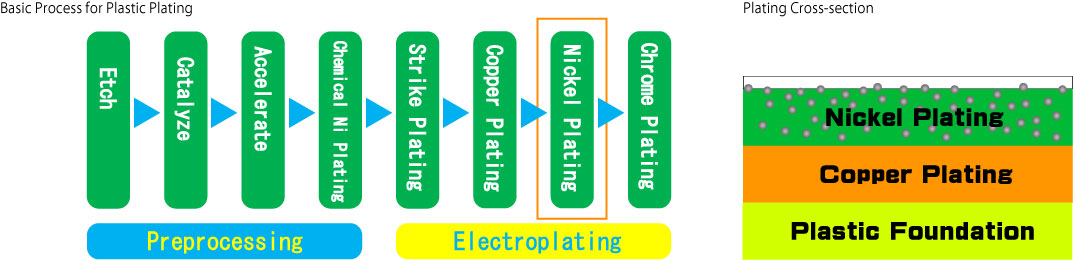

Mechanism of Satin Plating

During the Satin plating process, a special process is performed during the electro-plating process of the Nickel plating layer to reduce the shine.

Conventionally, the glossy plating surface has a smooth surface, but in order to mute the shininess for the satin plating, there are microscopic emulsion particles in the plating solution.

When these emulsion particles are added during the plating deposition, they partially suppress the deposition, creating countless crater-like indentations. This causes a loss of glossiness, resulting in satiny texture.

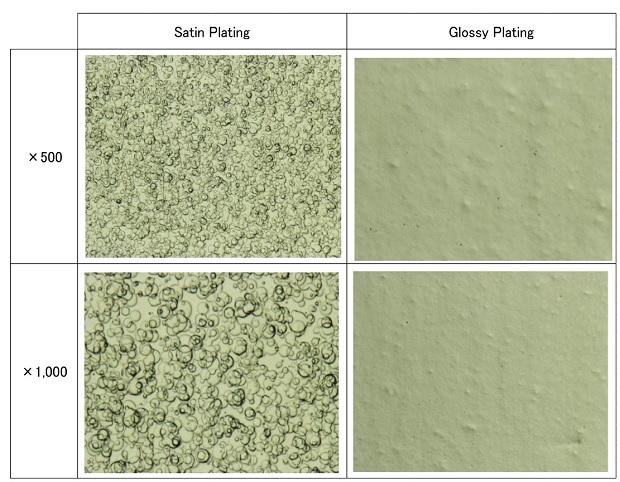

Results of Electron Microscope Observations

-

By observing glossy and satin plating surfaces through an electron microscope, the roughness of the surface for the satin plating finish becomes noticeable.

The amount and size of the roughness changes the kind of satin appearance.

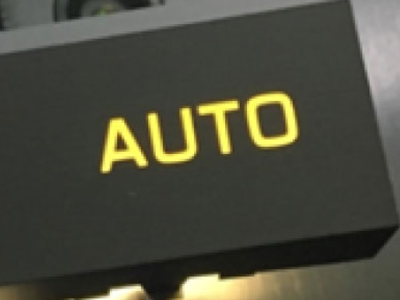

Translucent Buttons

TRANSLUCENT BUTTON

By using a special process on items being plated, letters and symbols can be inserted, to create a button that is lit from behind the surface.

-

Unlit Appearance

-

To hit the light

-

Translucent letters, etc.

Recently, these have become prevalent in high-end American and European automobiles.

-

-

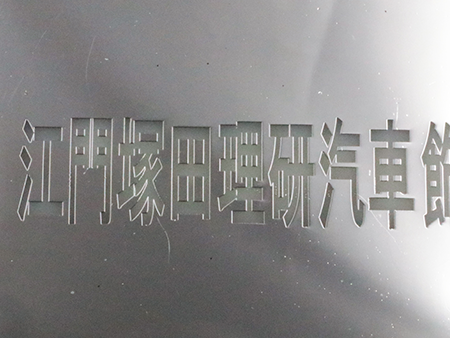

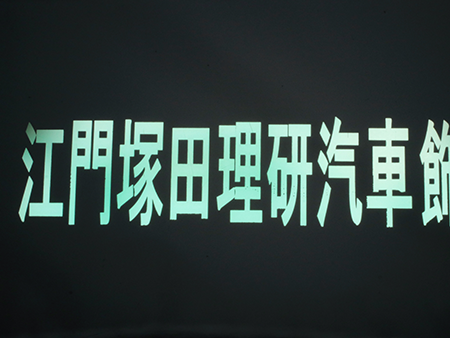

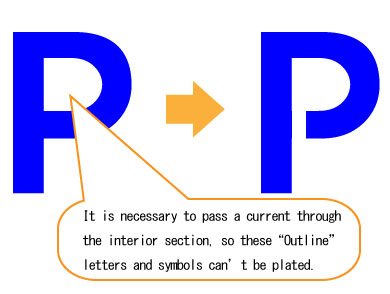

For normal translucent plating, when, the interior section of “Outlined Letters” (letters and symbols that have interior sections, like the triangle in the capital “A”) can’t be plated. Therefore, translucent plating has been limited to simple letters and symbols.

-

With our patented “Outline Character Translucent Plating Technology”, we can apply strongly adhesive plating to the interiors of letters, allowing us to even create sharp translucent plating of such complex letters as Chinese characters.

-

-

Standard plating of stencil-type letters

-

Our Translucent Plating for Outlined Letters

-

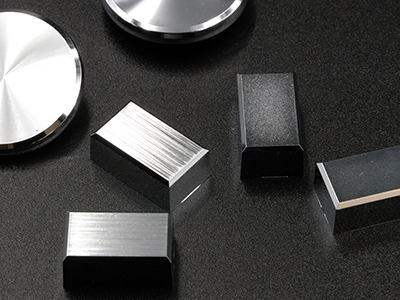

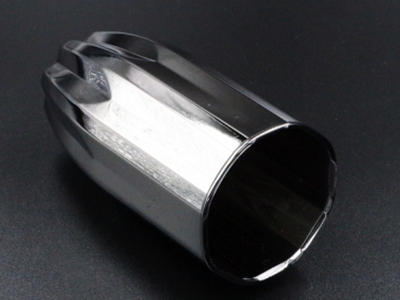

Hairline / Grain

HAIRLINE / SHIBO

-

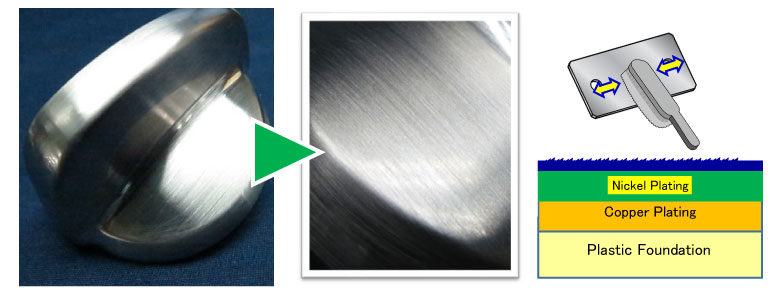

Hairline Processing 1 ~Processing after plating~

Hairline Processing involves running a brush over the surface after the plating process. This enhances the metallic look of the plating.

-

Hairline Processing 2 ~Processing the Mold~

By applying hairline processing to the mold, the hairline design is created directly on the molded plastic material. Then a very thin layer of plating is applied, so as not to fill in the hairlines.

Creating the design on the mold allows for fine designs, which are suited for mass production. However, as the plating is not thick, corrosion resistance is limited.

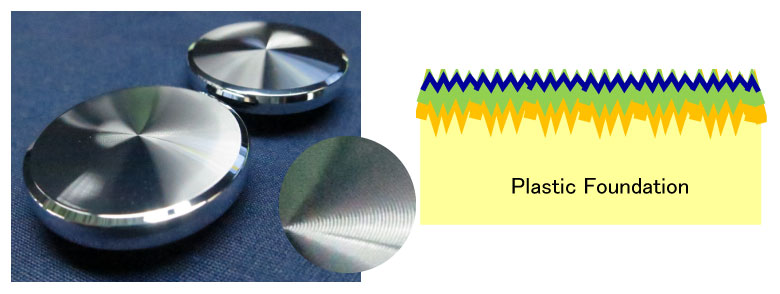

Grain Processing ~Processing the Mold~

-

- By applying a highly adhesive thin plating to designs and textures created on the surface of the material, these features can be preserved even after plating.

By adding plating, detailed designs and textures can be made to stand out.

-

By selecting the plating specifications to best correspond to the intended use, it is possible to accent the appearance of diamond-cuts, hairlines, and textures created on the plastic.

-

This thin plating is meant to maximize the impact of diamond-cuts, hairlines, and other textures that are molded into the surface of the plastic.

Blue Plating

BLUE PLATING

-

Blue Colored Plating

-

We have added a bright blue metallic decorative plating to our line-up. Normally, to create a metallic color, it is standard to paint a color over the chrome plating. However, depending on the application, the paint on the chrome plating may peel or wear off, so it is difficult to protect the surface color ever a long period of time.

With our ion plating technology, items plated in our bright blue plating have strong adhesion, so they don’t peel, and the plating increases the object’s hardness.

This is especially popular for futuristic looks, such as the emblems and ornaments on electric cars.

Please contact us for more information.

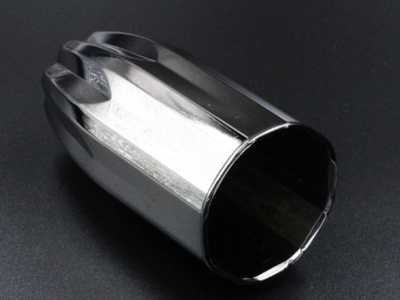

Antiqued Plating

ANTIQUE PLATING

-

By adding a process after the plating process, we have been able to create a plating finish with an antique look.

-

A layer of black plating is added as the top coat, then brushed off, to reveal the next layer of plating.

Characteristics of Antiqued Plating

With our proprietary technology, we can process the surface to give it an antique look with high corrosion resistance.

Therefore, it can be applied for many purposes

.

※As the topmost layer of plating is brushed off, the corrosion resistance may not be sufficient for some applications.

Anti-corrosion Plating

SALT DAMAGE PLATING

For Russia High Calcium Chloride Corrosion Resistance Trivalent Chromium Plating

-

External Part Plating (for cold climates)

High Calcium Chloride Corrosion Resistance

Special Trivalent Chromium Plating -

Cars have become ubiquitous throughout the world, which means that the exterior parts are subjected to a wide range of weather conditions.

Especially in colder climes like Russia, snow-melting agents (such as calcium chloride) are hard on plastic plating, causing the plating to peel. And so the need for plating that is resistant to such cold locations has arisen.

We have sought a solution to the corrosion caused by calcium chloride in these colder regions, developing trivalent chromium plating for this purpose, and we have already begun mass production.

CL Plating Coat for Salt Damage Environmental Evaluation Test Results

①Plating Specifications TP-10CL (Special Trivalent Chromium Plating for Calcium Chloride Resistance)

②Evaluation Sample Material ABS plastic (natural)

③Plating thicknesses(units;μm) Copper 13.5 Nickel 11.7 CL plating 0.23

| - | Test Method | Test conditions | Evaluation Standards |

|---|---|---|---|

| (1) | Corrodkote Test | 16 hours | No rust / discoloration (no more than 10% local corrosion) |

| (2) | CASS Test | 30 hours | No rust/discoloration |

| (3) | Salt Spray Test | 72 hours | No rust/discoloration |

| (4) | Temperature Cycle Test | 4 cycles(※1) | No blistering |

| (5) | Anti-corrosion / rust test | 2 cycles(※2) | No discoloration / blistering / cloudiness |

※All tests are performed and evaluated in accordance with JIS standards.

※1{-30℃/1 hr → room temp (20℃)/15 min → 70℃/1 hr → room temp(20℃)/1 hr} × repeated 4 times

※2 Test mud applied → indoor drying (1 hr) → -20℃/15 hrs → 35℃, 60%/ 5 hrs × twice

| - | Test Method | Test Results | Decision |

|---|---|---|---|

| (1) | Corrodkote Test | No rust / discoloration | OK |

| (2) | CASS Test | No rust / discoloration | OK |

| (3) | Salt Spray Test | No rust / discoloration | OK |

| (4) | Temperature Cycle Test | No visible defects | OK |

| (5) | Anti-corrosion / rust test | No visible defects | OK |

Painting

PAINTING

-

Processing scenery

- Our factory is at an elevation of 622m, and the paint booth is even higher – on the top floor of the 25m high 4-story factory. Perhaps the greatest asset is the clean air, coming from the snowmelt and the endless forests of the beautiful Chou Alps. While this naturally leads to better product quality, a healthy factory setting is also important for the employees who work here.<br />Once called the “Machu Picchu of the painting industry” by a customer due to the high location of the equipment, some have said the placement is unusual and illogical, but it has many merits, and our ideas and outside-the-box thinking have created a cutting-edge booth. Now, our customers say, “We can tell how reliable it is just by looking at it”, and we have increased the variety of things we can do.

Integrated Production System

【Mold】→【Casting】→【Plating】→【Painting/Printing】→【Assembly】

We can paint or print on plating for you!

-

If we are given the design, we can perform integrated production, from making the mold, casting the object, plating it, painting or printing on it, through to the final assembly.

As a plating manufacturer, we can maintain unwavering quality with the painting and printing on the plated surface.

We are also able to perform many types of partial painting.

While keeping the high decorative quality of the plating, we can also recommend ways to even further decorate the product.

There are various ways of masking, and our precision is as close as 0.3 mm~. -

-

Partial Painting on Plating

-

Specially Printed Plating

-

Trivalent Chromium Plating

TRIVALENT CHROMIUM PLATING

In Europe, a regulation forbidding the use of hexavalent chromium in new cars is expected to be put into effect.

And electronics manufacturers are expecting to see the same EU regulation.

And even domestically in Japan, major electronics manufacturers are moving away from the use of hexavalent chromium, which is considered a hazardous substance.

Environmental Regulations

Hexavalent Chromium Plating

The anti-corrosion and corrosion-resistance properties are strong, and it doesn’t react with the atmosphere, so this chemical has been widely used in a multitude of surface processes.

However...

1) The cost is low due to ease of production.

2) Compared with other anti-rust coatings, anti-corrosion and corrosion-resistance properties are markedly superior.

3) Operation and bath management are relatively simple.

At the present, no replacement has been found that can match all of its characteristics.

Environmentally Friendly Plastic Plating Methods

-

In regards to the small amount of mist, the ease of waste-water processing, the evenness of the coating, and the ease of removing impurities, Trivalent Chromium plating is the best substitute technology for Hexavalent Chromium plating.

We are a pioneer in the industry, succeeding in creating an all-automatic plating line for environmentally friendly trivalent chromium plating. It is capable of both white and black types of plating.

We are a pioneer in the industry, succeeding in creating an all-automatic plating line for environmentally friendly trivalent chromium plating. It is capable of both white and black types of plating. -

-

White Trivalent Chromium Plating<C3>

-

Black Trivalent Chromium (TI) Plating

-

IP (Ion Plating)

ION PLATING

-

Processing scenery

- on Plating is a technology for a thin surface-coat process, which was developed in the United States as part of the space-development technologies. A kind of PVD (physical vapor deposition), it has better adhesion than vacuum deposition or sputtering, and can be used to manufacture hard coats such as TiN (titanium nitride).

With our original ion plating technology, we are able to use a low-temperature process to perform ion plating directly onto the plastic plating product. Ion plating provides a surface that is much harder and corrosion-resistant than can be attained with standard plating. The available colors are bright gold, pink gold, silver, and gun-metal gray.With our original ion plating technology, we are able to use a low-temperature process to perform ion plating directly onto the plastic plating product. Ion plating provides a surface that is much harder and corrosion-resistant than can be attained with standard plating. The available colors are bright gold, pink gold, silver, and gun-metal gray.

Characteristic

-

- Superior Adhesion

- With a hard titanium nitride (TiN) coating, the surface is more scratch-resistant than chrome or gold plated surfaces.

- High Wear-resistance

- Titanium nitride (TiN) provides high corrosion resistance (also highly resistant to environmental color deterioration).

- With low-temperature processing, we can accommodate many plastics (ABS, PC, PA, LCP, PBT, etc.)

- Gold and Gun-metal gray are the basic colors. For other colors, please contact us.

-

-

ITI(Gun-metal gray)

-

Blue Plating

-

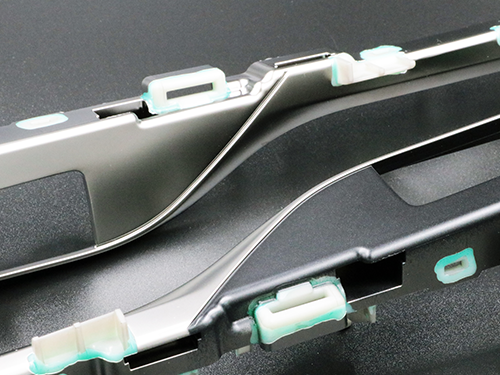

2-color Molded Part Plating

TWO-COLOR MOLDING PLATING

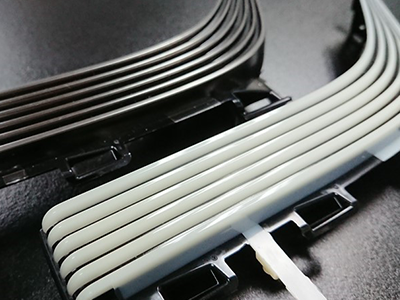

Plating on 2-color Molded Parts

-

Bottom: before plating

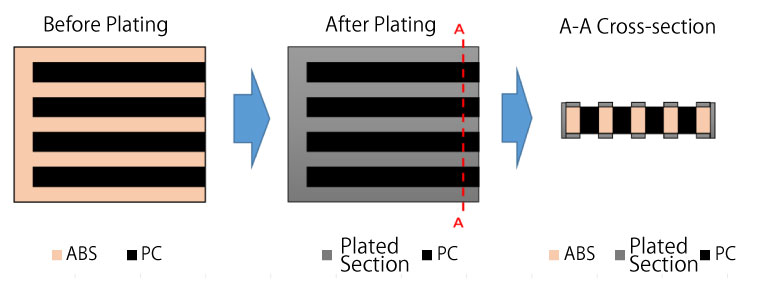

Top: after plating - When performing the standard plating process, if a part has been molded from 2 kinds of plastic (deposit-friendly ABS and deposit-resistant PC (poly-carbonate)), it is possible to execute a design for a single part that contains both the plastic color and the plated color.

In this way, design possibilities are increased by allowing for plastic parts with a clear division between the plastic and the plating.

Also, when inserting a plated part into another, it is possible to create non-plated sections for the inserted or bonded parts, which results in less gaps or friction noise (squeaking) after assembly.

2-color Molded Part Schematic

<Caution> Contact points are necessary for plated areas (ABS sections). (Plating will not deposit on non-contact isolated sections.)

Plated areas on 2-color Molded Parts

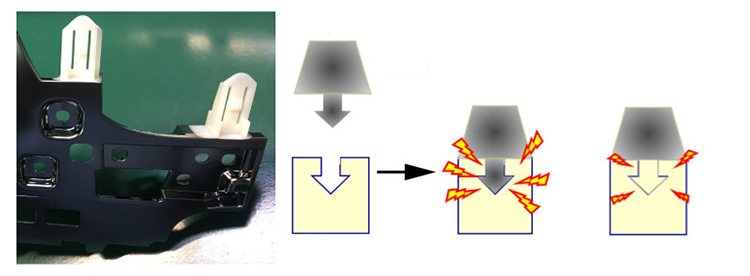

Preventing Squeaking

When plated pieces are in contact with other plastic pieces after assembly, the friction between the pieces will result in a “squeaking” noise. In order to prevent this, it has been standard practice to insert a fabric cushion between the pieces, but this can be avoided by using the TP mask method or 2-color molded parts. These methods can also minimize gaps between pieces,

increasing the level of precision. This is used in many domestic high-end cars.